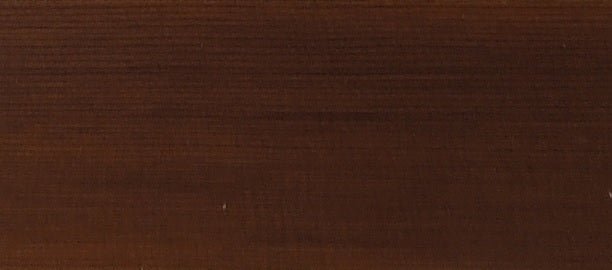

Please Note: Colours were developed to appear in harmony with their respective wood species e.g. 426 Larch for Larch wood projects. The wood’s natural colour and character will influence the final result. Plus, the darker the colour, the stronger the UV-resistance. Please always trial apply!

Osmo UV-Protection Oil Tints

Osmo UV-Protection Oil Tints - 5ml Sample Sachet / 425 - Oak is backordered and will ship as soon as it is back in stock.

Order in for free delivery

Free Next Working Day Delivery

Free Next Working Day Delivery

- Free Next Day Delivery on all orders (Please note that occasional delays may occur due to courier disruptions or stock availability).

- Orders placed before 3 pm will be dispatched on the same working day for delivery the next working day.

- Orders placed after 3 pm on Fridays will be dispatched first thing on Monday for delivery on Tuesday.

- Small items are shipped via Royal Mail with 24-hour tracked delivery.

- Large and oversized items are shipped via FedEx with next day tracked delivery.

- Tracking information will be provided via email or text once your order has been dispatched.

- We deliver to mainland UK only.

- Orders placed for delivery on a bank holiday or during our closure period will be dispatched on the next standard working day.

- Exclusions: Levelling compounds are not eligible for delivery

Click & Collect

Click & Collect

- Place your order online.

- Select the click & collect option at the checkout.

- You will receive email confirmation that your order is ready to collect (generally within 5 minutes)

Opening hours: 7am - 4pm Mon-Fri

Collection address:

Wiltshire Wood Flooring Supplies

Unit 1

Penton Business Park

Stephenson Road

Churchfields Industrial Estate

Salisbury

SP2 7NP

Description

Description

All exterior woods grey into a patina colour over time, however UV-Protection Oil Tints have been developed to maintain the wood's natural colour with the use of pigments to optimally match the wood's natural characteristics. Ideal for windows, doors, cladding, fencing and other vertically structured joinery (not recommended for flat surfaces such as decking).

Natural oil-based and microporous finish does not crack, flake, peel or blister. Water and dirt resistant, moisture regulating and reduces wood swelling and shrinkage. Osmo 425 Oak UV Protection Oil gives optimal protection from the sun, similar to Osmo 420 but it improves the UV resistance further by also having a small amount of Oak pigment. The oak pigment will darken the wood slightly and accentuate the wood grain but we recommend ALWAYS do a test before application, sample sachet available. For exterior use only.

Especially recommended for vertical surfaces such as timber cladding, windows and doors Prolongs the renovation time significantly when used as a top coat for staining wood Contains active ingredients for the preventative protection against algae and fungal decay.

Key Benefits

Coverage (m2) per Litre: 18

Base: Solvent

Paint Application: Brush, Roller

Suitable Substrate: Exterior Woodwork, Window Frames, Doors

Exterior: Exterior

Drying Time: 12 Hours

PREPARATION

Wood surface must be clean, dry and frost-free (moisture content max. 20%). UV-Protection-Oil Tints is ready to use. Do not thin. Stir well using a flat stirring stick or spatula before use. Ideally, surfaces are sanded no finer than a P120 grit grade of sand paper. Sanding to finer grades will reduce required absorbency.

If possible, and if the wood is absorbent, please apply first coat to all sides before installation. Fresh wood containing natural wood ingredients /extractives (eg: Cedar, Teak, Mahogany or Iroko) are often less absorbent and need to weather off first before applying the product. Please refer to website ‘Suitability’ section for more details. Weathering helps ingredient rich wood become more absorbent and the wood finish adheres optimally.

For renovation works, clean old microporous stains thoroughly – if necessary sand lightly. Clean and restore already greyed or weathered wood at the same time with Osmo Wood Reviver Power-Gel. Old paints and lacquers must be completely removed. As a general rule, wear a dust mask during sanding works. To maintain absorbency, avoid sanding surfaces finer than a P120 grit. Weather ingredient rich wood after sanding.

The finished surface is influenced by several factors, including the condition of the wood. Therefore, a trial application is always required, especially for unfamiliar surfaces.

Soft wood species like Pine or Spruce are more prone to blue stain, rot and insects. If desired, pre-treat these soft woods if possible on all sides with Osmo WR Base Coat.

APPLICATION

With Osmo Flat Brush or Osmo Microfibre Roller, apply thinly along the wood grain and spread well.

Allow to dry for approx. 12 hours under good ventilation.

Then apply the second coat.

Alternatively the second coat can also be carried out with UV-Protection-Oil Extra Clear.

When recoating colour treated surfaces, or for renovation works, one coat applied to the clean and dry surface is usually sufficient.

FAQs

FAQs

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.