Osmo

Osmo End Grain Sealing Wax Clear 375ml (5735)

In stock (6 units)£20.19£22.44Unit price /UnavailableOsmo

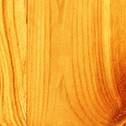

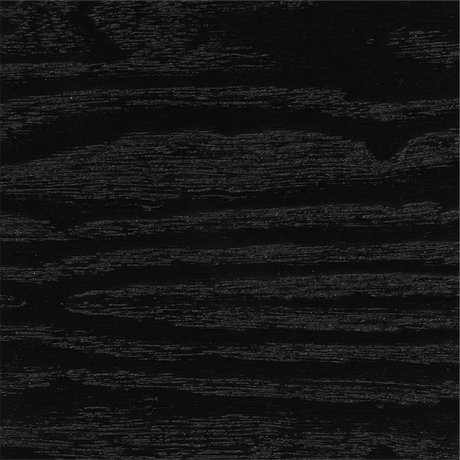

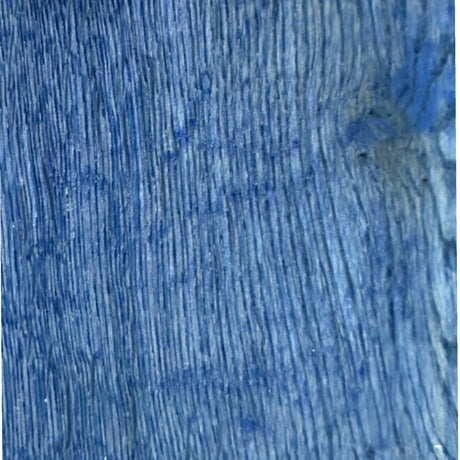

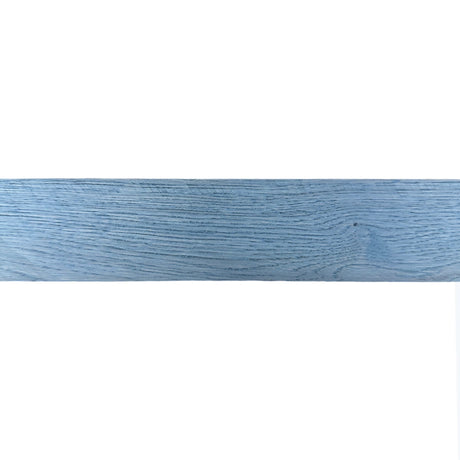

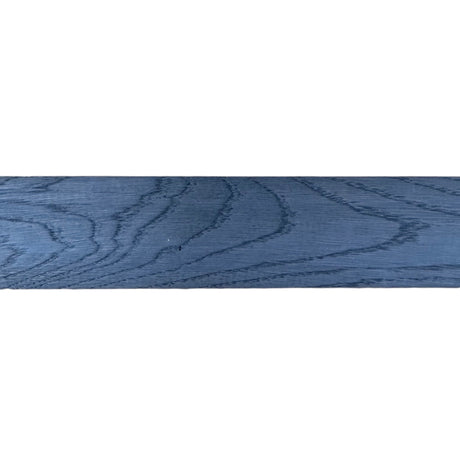

Osmo Polyx -Oil Tints – Tinted Hardwax Oil for Wooden Floors & Furniture

+3In stock (72 units)From £3.99Unit price /UnavailableMorrells

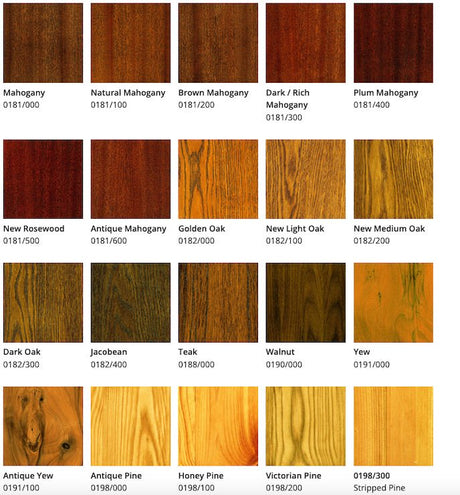

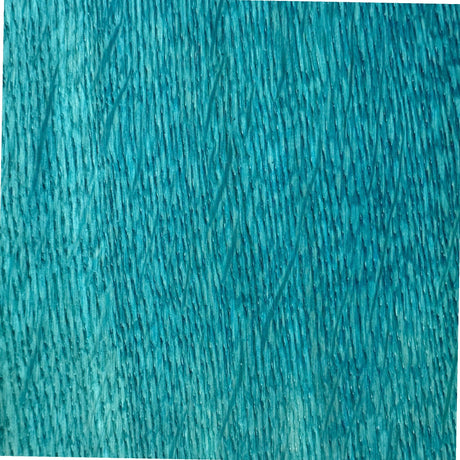

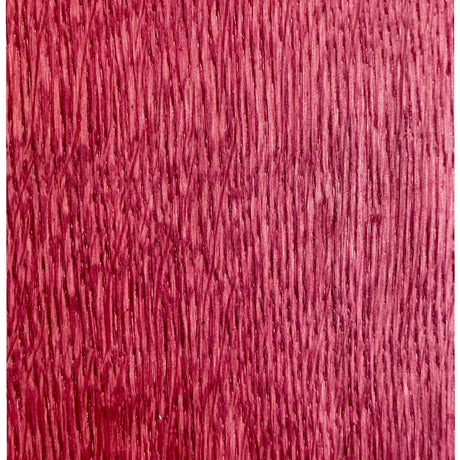

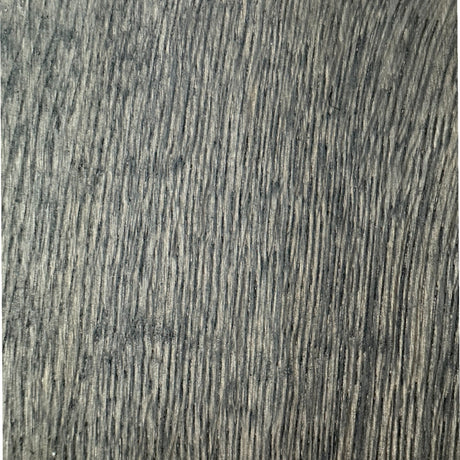

Morrells Light Fast Wood Stain

+24In stock (3042 units)From £5.01Unit price /UnavailableBona

Bona Natural & Mega EVO Lacquer Bundle (50m2)

In stock (2 units)£369.71Unit price /Unavailable